About our new IP Containers website!

July 20, 2021

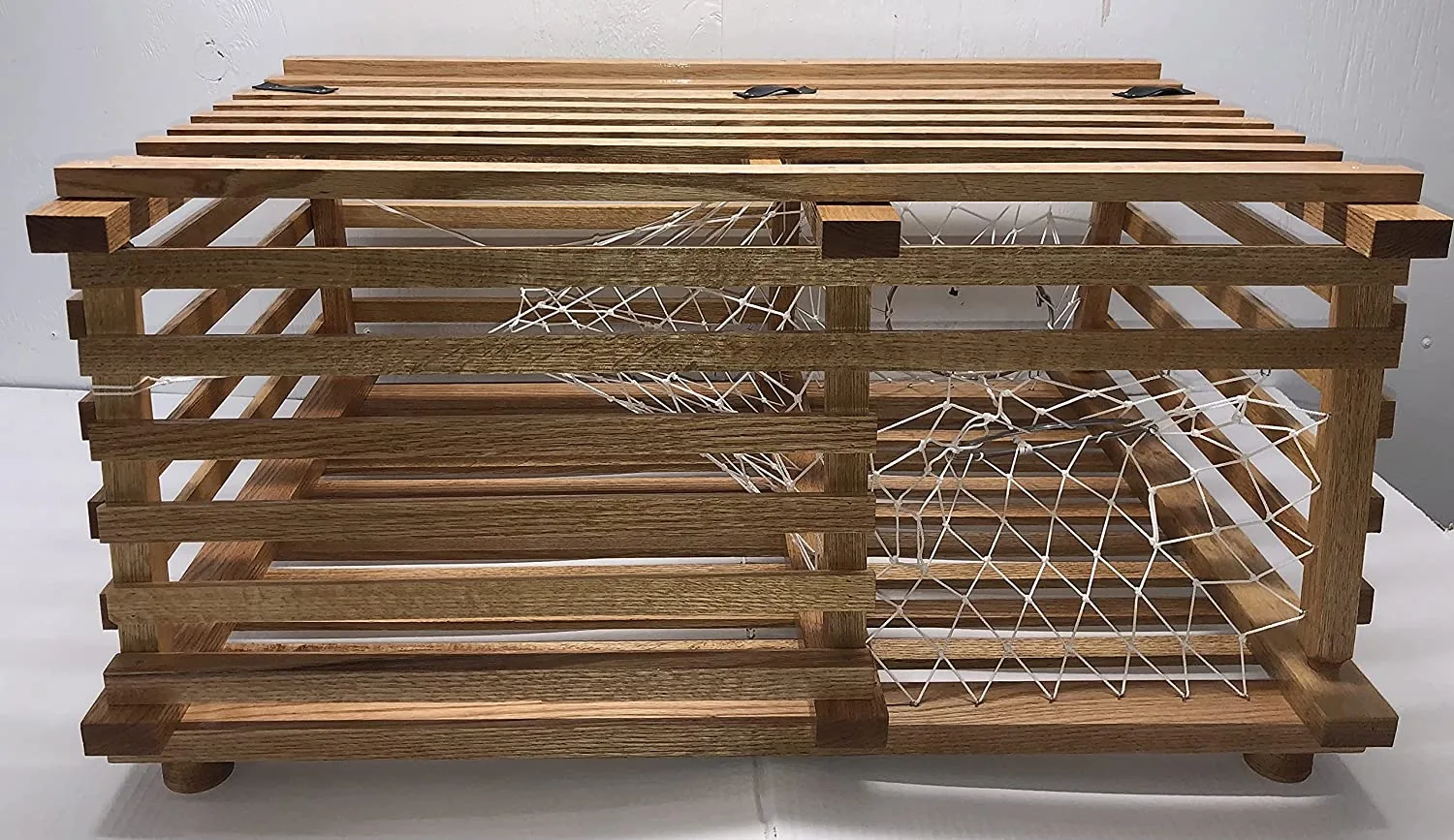

Transport Crates in the Past and Today

Crates and containers made of wood for many years were the only way of transporting and storing loads available on the market. They have been used in almost every industry. However, more and more often, we are giving up packaging made of natural raw materials in favor of plastic boxes that can be recycled.

Plastic crates for lobsters are designed to make the best use of space and provide universal storage and transport solutions as an alternative to wooden crates. They have many uses and advantages, which is why they are increasingly being bought by entrepreneurs.

A variety of polypropylene containers are used in many industries, from food, through fish and seafood processing to automotive and medical.

Many crates are versatile, some series are produced for specific services, such as transporting fruit and vegetables, storing fish and other marine animals, or transporting medicines and medical products. Why are plastic lobster crates better than traditional wooden crates? How are they different and which will be the best choice for your company?

Production of wooden and plastic lobster crates

Over the centuries, the construction of wooden crates has been successively improved so that they can withstand the greater weight and meet more difficult transport challenges. Wooden crate manufacturers have found ways to strengthen the lobster containers by including, for example, metal components.

However plastic crates are easier and more cost-effective to produce in large numbers. Plastic crates come in a variety of color options, which makes them more attractive than wooden crates when used for retail display. Advanced technologies used during production allows for the adaptation and modification of the designed plastic container, to meet the needs of a given enterprise or factory. This makes their production easier and more versatile.

Life Span

Both types of lobster crates are to be used for years, not just in one transport. Wood is one of the more durable materials, but due to the many components used in production, such as boards and nails, it is more likely to deteriorate or fall apart during transport.

Crates made of plastic can be used responsibly for up to 10 years, which generates significant savings in the long run. Additionally, they are resistant to UV rays, which can destroy the structure of the box and the contents stored in the wooden lobster box.

Depending on the needs, plastic crates ensure tightness or proper ventilation of the product, preventing it from losing its freshness.

Resistance to External and Atmospheric Factors

Wooden lobster crates have been used by mankind for hundreds of years. Over time their durability and the method of assembly were successively improved. However, even the most expensive crates made of wood are exposed to many external factors that can damage the crates and the products stored in them.

Storing wooden crates in the open air or a place exposed to water ingress may end up in an unpleasant surprise. Wooden lobster crates can break down due to precipitation resulting in insufficiently protection of stored products from water and moisture.

These dangers do not apply to plastic crates. They are not indestructible, but they do not break or break as quickly as wooden ones. They do not contain screws and other metal elements that could loosen and lead to the disintegration of the entire box. They are smooth, without burrs and sharp splinters. Therefore, they are safe for the people who use them and for the products stored inside.

Unlike wood, the plastic walls of the crates will not let fluids pass through from the outside. If the structure of the plastic crate has not been damaged, it is resistant to seepage or water ingress. Lobster crates such as those available on the IP Containers website provide great protection for the stored product, even during rain or snowfall.

Weight and Transport

Wood belongs to the group of light materials, but plastic is one of the lightest materials used in production and transport. Wooden containers can gain extra weight as water soaks into the wooden structure.

The low failure rate of plastic boxes facilitates collision-free and smooth operation of transport lines. Plastic crates are much lighter, thanks to which transport costs are significantly reduced, and their transport is much simpler and less time-consuming.

Previous

Next

Protection Against Pets and Bacteria

More and more enterprises and factories notice the dangers of storing products in wooden crates. Wood does not provide full protection and is not an obstacle for some pests or insects.

For safety and hygiene, plastic boxes are used during production and transport, which protect the stored product and ensure its freshness.

Because plastics do not absorb moisture, plastic lobster crates are not exposed to fungi and mold. At the same time, they are resistant to damage caused by insects, rust, and corrosion, as well as fats and oils.

Hygiene and Cleaning

Every year hygiene in the workplace becomes more and more important. During production, speed and time savings are factors that influence the entire process and often determine the success of the company.

Enterprises and factories care about the best possible optimization of production, as well as hygiene in the workplace and cleaning processes. Plastic crates are up to 30% lighter than those made of wood. The great advantage of plastic crates like IP Crates and IP Trays made of high-quality raw materials is that they are much easier to clean.

This makes it easier for workers to clean and disinfect them and makes them easier to keep clean and requires little maintenance. Plastic crates do not need to be impregnated or varnished and can be with strong chemicals.

Plastic crates easily undergo disinfection processes that prevent the multiplication and transmission of dangerous viruses and bacteria. This has a very large impact on the safety of employees during the pandemic. The smooth, uniform surface of plastic crates facilitates washing processes, which results in considerable savings in time and money.

We must also remember that wood is a material that increases the risk of damage to goods and injury to workers in the transport and storage process. Busy businesses cannot afford these types of accidents. Contrary to wooden crates, plastic lobster crates do not contain protruding nails or come across splinters and wood fragments that can be dangerous for workers.

Durability and Repair

Traditional wooden crates can indeed be used multiple times, but there is a limit to the total number of uses before the structural integrity of the crate is compromised. Wooden containers are also prone to chipping when struck. Loose or rusty nails and screws can also damage livestock packaging, damage the interior of a truck or ship, and cause damage or injury to warehouse or boat personnel. Wooden crates can be easily repaired by replacing worn boards, but it is an extremely labor-intensive job.

Durable plastic lobster crates are reusable and can be used much longer than wooden crates, while the structural integrity of the crate remains strong and stable throughout its service life.

Plastic containers have a durable and rigid structure that should ensure their durability for years. Unfortunately, during use, they can still be damaged. Compared to wooden lobster crates, repairing them may turn out to be more expensive and require more professional equipment than boards, nails, and a hammer. However, the negligible failure rate of plastic crates facilitates the collision-free and smooth operation of the transport lines.

Versatility and Adaptation to Production

Wooden crates are still used in many enterprises and industries, such as horticulture. However, their weaker structure and variety in production pose many problems related to storage and transport.

When buying, it is worth considering that the wood will warp over time and it will no longer be possible to place it evenly in vertical rows, so choose crates covered with angles if possible – they will reduce the rate of loosening of the wooden crate structure.

Plastic boxes are very stable and durable; therefore, they fully protect the products during transport and storage. Their universal design allows them to be stacked (which provides the benefit of saving valuable storage space). They are perfect for cold stores; they can be easily moved with forklifts.

Diversity also speaks in favor of this type of crate. Manufacturers offer many models with different parameters and methods of wall finishing (including those with doors built into the sidewall), which gives more flexibility in choosing the right container for lobsters.

Manufacturers of wooden lobster crates cannot boast of similar creativity, and their products, as a rule, are very similar to each other. The use of plastic also makes it possible to stick labels to facilitate the identification of the cargo.

Thanks to the wide range of available labeling/marking technologies (e.g., screen printing), it is possible to place not only simple texts on them but also complex, multi-colored graphics.

Ecology and Recycling

The theme of ecology is becoming more and more important, also in industry and trade.

At first glance, it is difficult to consider a material that decomposes in nature for several hundred years as a more ecological solution. However, it is worth remembering that, just as plastic is not always harmful to the environment, wood is not always the best for a specific application. After all, a lobster crate made of plastic has nothing to do with a plastic straw or a plastic supermarket bag.

Their service life sometimes exceeds 10 or more years, which generates considerable savings in the long run. Contrary to appearances, plastic lobster containers are environmentally friendly – firstly, they do not require further logging, and secondly, they are reusable and recyclable.

Unlike wood, plastics do not need to undergo extensive chemical and thermal treatments.

This means that our plastic crates are the perfect choice to breathe new life into a large proportion of the plastic waste generated in our consumer society and industry value chain.

This makes them an excellent example of the circular economy that is now the target of all self-respecting companies.

The Price of Wooden and Plastic Crates

The price is also important – plastic lobster crates are usually more expensive. However plastic boxes significantly reduce the costs of storage and transport. On the market, we can find transport containers of various quality and prices. However, in most cases, wooden crates will be cheaper than plastic ones.

It must be remembered that the production of wooden crates has been known for hundreds of years all over the world, and plastic crates have been developed and started to be produced relatively recently.

That is why we can still meet a lot of people in the world who only use wooden crates – which may be due to their durability, as well as the habit of using them for generations. However, many companies have already recognized the benefits of using plastic lobster crates and have replaced the wooden crates with plastic boxes.

Products that must be constantly invested in to keep them in good condition are unprofitable. Even if they seem much cheaper in the store, the costs of their use will significantly strain the company’s budget. That is why it is worth investing in plastic lobster boxes that will last for many years without the need for frequent repairs.

The higher price of a plastic container quickly ceased to be of great importance, as their owners can use them for several years, while at the same time the owner using wooden boxes had to replace them once or even several times with new wooden containers. Over the years, the cost of purchasing plastic containers has paid off. By investing in plastic lobster boxes once, you will use them many times. Therefore, in the long run, they will prove to be a cheaper solution than wooden containers.

It’s Your Choice

The wide range of lobster crates available on the market has made it difficult to choose the right one. Both wooden and plastic boxes have their strengths and weaknesses. However, it is wooden crates that are slowly being phased out of use and production.

On the other hand, in almost every lobster processing plant or fishing boat, we can find plastic containers like IP Lobster Crates. Because they are impermeable to moisture, as well as acids and alkalis, they can be used in more industries. They can also be stored in cold stores or outside because the plastic is resistant to various weather conditions.

The companies that chose plastic containers found that they reduce waste and provide a cleaner environment and safety for employees and customers. In the future, we may see even more benefits of using plastic lobster containers.